How Is A Solar Panel Made?

Solar panels have become a cornerstone of renewable energy solutions, providing a sustainable way to harness the power of the sun. Understanding how a solar panel is made can offer insights into the technology that powers our homes, businesses, and even entire cities. This article will delve into the intricate process of manufacturing solar panels, from raw materials to the final product, and address some common questions and concerns.

The Basics of Solar Panel Technology

Before diving into the manufacturing process, it's essential to understand the basic components and functionality of a solar panel. A solar panel, also known as a photovoltaic (PV) panel, converts sunlight into electricity. It consists of multiple solar cells, which are the fundamental units that perform the energy conversion. These cells are typically made from silicon, a semiconductor material that is abundant and efficient at converting sunlight into electrical energy.

Step-by-Step Manufacturing Process

1. Raw Material Extraction

The primary material used in solar cells is silicon, which is derived from sand. The process begins with the extraction of high-purity quartz, which is then refined into metallurgical-grade silicon. This silicon is further purified to produce polysilicon, the raw material for solar cells.

2. Ingot Formation

The purified polysilicon is melted and formed into ingots, which are large, cylindrical blocks of silicon. There are two main types of ingots: monocrystalline and polycrystalline. Monocrystalline ingots are made from a single crystal structure, offering higher efficiency but at a higher cost. Polycrystalline ingots are made from multiple crystal structures, making them less efficient but more affordable.

3. Wafer Production

The ingots are then sliced into thin wafers using a wire saw. These wafers are typically about 200 micrometers thick. The slicing process must be precise to ensure uniformity and minimize waste. The wafers are then polished to remove any saw marks and to prepare them for the next steps.

4. Doping

To enhance the electrical properties of the silicon wafers, a process called doping is used. Doping involves adding small amounts of other elements, such as phosphorus or boron, to create a positive (p-type) or negative (n-type) charge. This step is crucial for creating the p-n junction, which is essential for the photovoltaic effect.

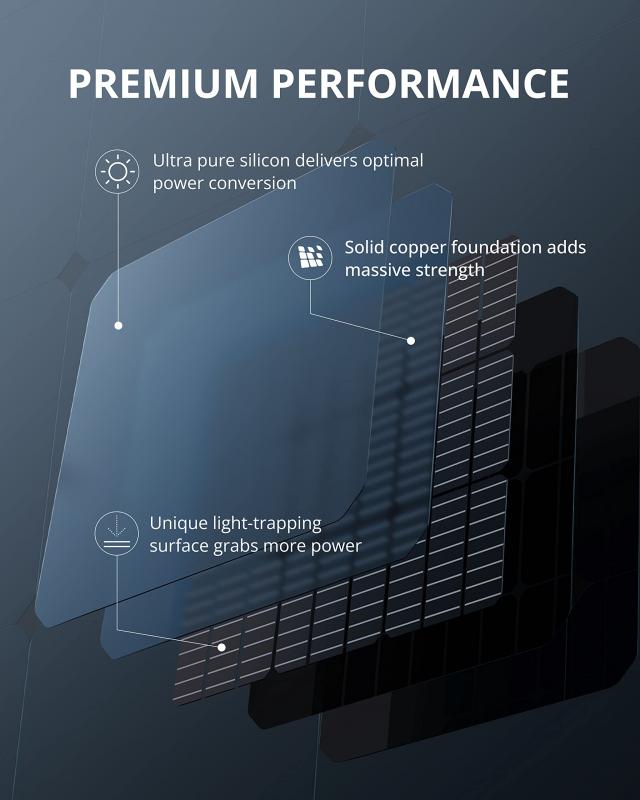

5. Anti-Reflective Coating

Silicon wafers naturally reflect a significant amount of sunlight, which can reduce the efficiency of the solar cells. To mitigate this, an anti-reflective coating is applied to the surface of the wafers. This coating, usually made of silicon nitride, helps to increase the amount of light absorbed by the cells.

6. Metal Contacts

Next, metal contacts are added to the front and back of the wafers to allow the flow of electricity. The front contacts are typically made of fine silver lines, while the back contacts are usually made of aluminum. These contacts are applied using a screen-printing technique and then fired in a furnace to form a solid connection.

7. Cell Testing and Sorting

Once the solar cells are complete, they undergo rigorous testing to measure their efficiency and electrical output. Cells are sorted based on their performance, ensuring that only the highest quality cells are used in the final solar panels.

8. Module Assembly

The sorted cells are then assembled into solar panels. This involves arranging the cells in a grid pattern and connecting them with metal ribbons. The cells are encapsulated in a protective layer of ethylene-vinyl acetate (EVA) and sandwiched between a tempered glass front and a durable backsheet. The entire assembly is then framed with aluminum to provide structural support.

9. Quality Control and Testing

The assembled solar panels undergo a series of quality control tests to ensure they meet industry standards. These tests include mechanical load testing, thermal cycling, and exposure to simulated sunlight. Panels that pass these tests are certified and ready for installation.

Addressing Common Questions and Concerns

What is the environmental impact of solar panel production?

While solar panels offer a clean energy solution, their production does have an environmental footprint. The extraction and purification of silicon, as well as the energy-intensive manufacturing processes, contribute to greenhouse gas emissions. However, advancements in technology and increased use of renewable energy in manufacturing are helping to reduce this impact. Additionally, the energy generated by solar panels over their lifetime far outweighs the energy used in their production, making them a net positive for the environment.

How long do solar panels last?

Most solar panels come with a warranty of 25 to 30 years, but they can last even longer with proper maintenance. Over time, the efficiency of solar panels may decrease slightly, but they can still produce a significant amount of electricity well beyond their warranty period.

Can solar panels be recycled?

Yes, solar panels can be recycled. The recycling process involves separating the different materials, such as glass, aluminum, and silicon, and reusing them in new products. As the solar industry grows, so does the infrastructure for recycling, making it an increasingly viable option for end-of-life panels.

What are the latest advancements in solar panel technology?

The solar industry is continually evolving, with new technologies emerging to improve efficiency and reduce costs. Some of the latest advancements include:

- Perovskite Solar Cells: These cells offer high efficiency and can be produced at a lower cost compared to traditional silicon cells.

- Bifacial Solar Panels: These panels can capture sunlight from both sides, increasing their overall energy output.

- Flexible Solar Panels: Made from thin-film technology, these panels are lightweight and can be used in a variety of applications, including portable solar chargers and building-integrated photovoltaics (BIPV).

The process of making a solar panel is a complex and intricate one, involving multiple steps and advanced technologies. From the extraction of raw materials to the final assembly and testing, each stage is crucial in producing high-quality solar panels that can efficiently convert sunlight into electricity. As technology continues to advance, we can expect even more efficient and cost-effective solar panels, further solidifying their role in our transition to a sustainable energy future. Whether you're considering installing solar panels on your home or simply interested in the technology, understanding how they are made can provide valuable insights into this transformative energy solution.

There are no comments for this blog.